types of notches in impact test|machining notches for impact testing : sourcing The Charpy specimen may be used with one of three different types of notch, a 'keyhole', a 'U' and a 'V'. The keyhole and U-notch are used for the testing of brittle materials such as cast iron and for the testing of plastics. The V-notch specimen is the specimen of choice for weld . Resultado da IMDB Rating: 7/10 From 221 Users. Metacritic Rating: 85/100. Directed by: Savanah Leaf. Starring: Tia Nomore , Erika Alexander , Keta Price. .

{plog:ftitle_list}

22 de jan. de 2024 · The domain Tobets365.com belongs to the generic Top-level domain .com. It is associated with the IPv4 addresses 104.21.47.2 and 172.67.143.136, as well as the IPv6 addresses 2606:4700:3032::ac43:8f88 and 2606:4700:3036::6815:2f02. It appears that The site is a safe and legit website.

The Charpy specimen may be used with one of three different types of notch, a 'keyhole', a 'U' and a 'V'. The keyhole and U-notch are used for the testing of brittle materials such as cast iron and for the testing of plastics. The V-notch specimen is the specimen of choice for weld .Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. .The excess energy pendulum impact test indicates the energy to break standard test specimens of specified size under stipulated parameters of specimen mounting, notching and pendulum .

Four types of impact testing are described in detail below, encompassing the pendulum, drop-weight, and dynamic tear methods: 1. Charpy. The Charpy impact test, also known as the V-notch test, is a type of impact .

u notch testing

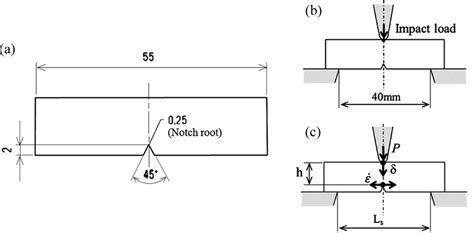

The type of notch introduced to a specimen depends on the material and characterization employed. For standardized testing of fracture toughness by the Charpy impact method, specimen and notch dimensions are most often taken from American standard ASTM E23, or British standard BS EN ISO 148-1:2009. For all notch types, a key parameter in governing stress concentration and failure in notched materials is the notch tip curvature or radius. For welding tests and ductile materials, the Charpy V-notch or also called CVN specimens are used worldwide. The dimensions of a standard Charpy-V specimen, shown in the below figure are 55 X 10 X 10mm with a .Impact test specimen types include notch configurations such as V-notch, U-notch, and keyhole notch. Impact testing most commonly consists of Charpy and Izod specimen configurations. .Impact test specimen types include notch configurations such as V-notch, U-notch, and keyhole notch. Impact testing most commonly consists of Charpy and Izod specimen .

Measurement and analysis of fracture behavior under high loading rates is carried out by different test methods. This article provides a discussion on the history and types of notch-toughness . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy impact test (see Fig. 6.9), which gives an indication of the toughness of a material at a specified temperature.It is not a particularly accurate test but can give a general indication of the ability .

1.1 - Pendulum Impact Test The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum-type impact load. The result is expressed in term of kinetic energy consumed by the pendulum in order to break the specimen. The energyCharpy impact test piece (V-notch, U-notch) Method for Charpy impact test of carbon fiber reinforced plastics: Test piece for flatwise impact . There are two notch types: V-notch and U-notch. The test pieces used for edgewise . Impact test specimen types include notch configurations such as V-Notch, U-Notch, Key-Hole Notch, as well as Un-notched and ISO (DIN) V-Notch, with capabilities of impact testing subsize specimens down to ¼ size. IZOD Impact Testing can be done up to 240 foot-pounds. on standard single notch and type-X3 specimens.

The resulting test sample measures 80 x 10 x 4 mm. The depth under the notch of the specimen is 8mm. Data: ASTM impact energy is expressed in J/m or ft-lb/in. Impact strength is calculated by dividing impact energy in J (or ft-lb) by the thickness of the specimen. The test result is typically the average of 5 specimens.Both Charpy & Izod impact testing are popular methods of determining the impact strength or toughness of a material. Learn comparisons from expert Lee Mangham. . Charpy vs Izod Impact Testing Comparison including materials tested, types of notches, position, striking point, dimensions, and common specifications.

Impact test specimen types include notch configurations such as V-notch, U-notch, and keyhole notch. Impact testing most commonly consists of Charpy and Izod specimen configurations. The Izod impact test differs from Charpy impact test in the way that the notch is positioned facing the striker. Thus in the Charpy test, the test piece is held . Charpy impact testing determines the impact energy of materials. . the specimen will begin to undergo plastic deformation at the notch. The test specimen continues to absorb energy and work hardens at the plastic zone at the notch. . affect the yield behaviour and hence ductility of the material such as temperature and strain rate will .In the Charpy test, you can expect two types of notches. One is the U-shaped notch, which is suitable for brittle materials to know their brittleness. On the other hand, a V-shaped notch offers the value for excellent impact-resistance materials. . Izod impact test creates a V-shaped notch at the middle of the metal or a slight low point in .

Two basic types of impact testing 1) Charpy impact test The specimen is supported as a simple beam with the load applied at the center. . Charpy test, the notch is positioned away from the striker. Types of Notch In the Charpy method, there are two kinds of notches, the V-notch and the U-notch, . 7U Ligament length, Type U 5 mm ±0.075 mm 8V Radius of notch, Type V 0.25 mm ±0.025 mm 8U Radius of notch, Type U 1 mm ±0.025 mm 9 Angle of notch 45° ±1° A Surface finish requirements 2 µm .

The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.This article provides a discussion on the history and types of notch-toughness tests and focuses exclusively on notch-toughness tests with emphasis on the Charpy impact test. It reviews the requirements of test specimens, test machine, testing procedure and machine verification, application, and determination of fracture appearance and lateral .

Methods for Notched Bar Impact Testing of Metallic Materials (E 23) has over the . While the addition of a notch was a major improvement in the test method, a test procedure was needed that would provide a continuous, quantitative . impact machine designers and manufacturers offered three major types; Drop Weight (Fremont, Hatt-Turner, and .

Charpy Impact Testing. Izod Impact Testing. Tested Materials . Plastics. Plastics. Types of Notches (0.25mm) Preferred. V-notch . V-notch . Specimen Position. Horizontally, Notch facing away from the pendulum. Vertically, . Type A has the Notch in the form of V, type B in the form of a keyhole and type C in the form of U. Charpy type specimens are supported centrally and the distance between these supports is 40 mm. The figure below . The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount of energy absorbed by the specimen during fracture.The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

ASTM D256 outlines the Izod impact test for plastics, emphasizing specimen preparation and machine calibration for accurate impact resistance data. . When injection molding specimens, it is important that cooperating laboratories be aware that the type of mold, the molding machine used, the machine set-up and the flow behavior within the mold .1.1 - Pendulum Impact Test The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum-type impact load. The result is expressed in term of kinetic energy consumed by the pendulum in order to break the specimen. The energyThe Izod impact test differs from the Charpy impact test in that the sample is in a cantilevered beam configuration instead of a three-point bending configuration. Notch toughness is a measure of the energy absorbed (impact energy) during the fracture of a specimen (in the presence of a flaw – usually a V-notch) of standard dimensions and .

types of plastic impact testers

Test methods used to measure Notched Izod Impact (or notch sensitivity) and Charpy Impact in plastics are: ASTM D256-10(2018): Plastics — Determination of Izod pendulum impact resistance; ISO 180:2019: Plastics — Determination of Izod impact strength; ISO 179-1:2010: Plastics — Determination of Charpy impact properties — Part 1: Non . The Izod impact strength test is another form of notch toughness testing. It is similar to the Charpy V-notch test in that it uses a pendulum and a notch that acts as a stress riser. However, in the Izod impact strength test, the specimen is placed with the notch facing the pendulum. The pendulum strikes the specimen just above the notch. The . In the Izod impact test, the notch is facing the pendulum. Type of Notches. All the stress from the impact gets concentrated on the notched section. Specimens break at the notched portions. Specimens for the Pendulum Charpy impact tester can have a V or a U shaped notch. Specimens for the Pendulum Izod impact tester only have V notches in them. How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog .

Types of Notches (0.25mm) Preferred V-notch V-notch Specimen Position Horizontally, Notch facing away from the pendulum Vertically, Notch facing towards the pendulum . The Multiaxial impact test provides full force and energy curves during the millisecond of the impact, using a “Tup” which incorporates an impact Test criteria for Charpy V-notch impact testing usually involve (i) a minimum impact energy value, (ii) shear appearance of fractured test bars expressed in percent, and (iii) lateral expansion. For steels, the minimum acceptable values generally specified for these three evaluation methods are 20 J, 50 % shear, and 1.3 mm respectively.

custom geotechnical soil moisture meter

types of impact tests

Últimas notícias do Acre no site do ac24horas.com. Acompa.

types of notches in impact test|machining notches for impact testing